The UK remains the ninth largest manufacturing nation in the world¹. However, the sector continues to face a real skills shortage, which has been well documented for years, leaving many asking, ‘how do you teach an old industry new tricks?’ Manufacturers consider the skills gap to be an enormous challenge².

Mick Goodwin, applications engineer at industrial 3D printing company, Markforged explores this challenge – and how industry and education are working together to address it.

PrintCity - Building the future, one layer at a time…

Manchester Metropolitan University is one institution tackling this challenge through its MSc in Industrial Digitisation and its 3D additive and digital manufacturing centre, PrintCity.

The PrintCity team see their purpose as ‘bridging the skills gap between education and industry’ – through innovation and collaboration. Attracting students from across disciplines including engineering and fine arts, PrintCity is providing them with access, hands-on experience and insight into technology and industry. The course attracts both BA and BSc undergraduate students.

Alan Dempsey, project manager at PrintCity, explained: “This is a course for everyone; one which we believe will truly enrich them and help to bridge the skills gap.”

Working together

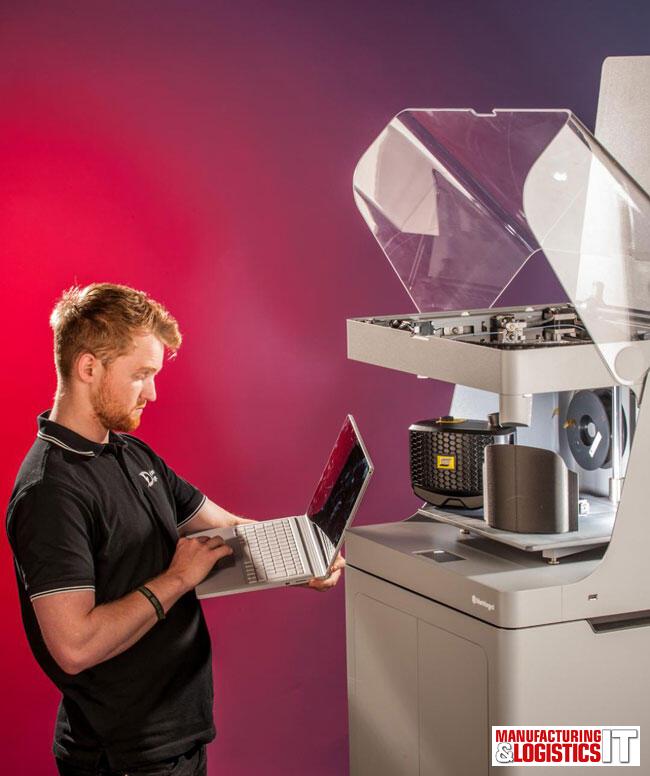

Education and industry have a huge role to play by working together to build for the future now. To help make this possible, companies like Markforged have teamed up with PrintCity to provide students with the opportunity to gain experience using the latest manufacturing technology as part of their degree programme.

PrintCity has deployed the full Markforged platform, giving students access to the complete range of industrial materials, from composite materials like carbon fibre and kevlar, to metals including stainless steel 17-4PH and pure copper. This access enables students to unleash their full potential and breaks down the barriers typically associated with turning their ideas into reality.

Alan Dempsey continued: “We want to bring students, the various faculties, business, and our technology partners together as part of one ecosystem. The purpose being to create new processes, new jobs and the future.”

As well as providing hands-on learning and teaching digital skills, the university seeks to hone the students’ soft skills through weekly internal round table sessions, which address more general business issues. The round table enables students to discuss the latest developments and how the technology is being used in multiple sectors, acting like CPD. This is because the technology, materials and applications are developing so quickly.

Alan Dempsey added: “When we designed the course, we developed 80% of the modules ourselves, but for the remaining 20% we brought in some large multi-national businesses – asking them ‘what they were missing from today’s graduates?’ It was this feedback that led us to developing the soft skills component.”

Bridging gaps and building careers

Mark Chester, a previous student on the PrintCity course, now works on the PrintCity Network programme. He commented: “PrintCity wants to create more rounded businesspeople; focused on the bigger productivity picture, as opposed to being focussed solely on a single technology. We really don’t want them to lose their wider creativity and skills.”

Now in its third cohort of students, PrintCity has always tried to build a community. Working as a multi-disciplinary team, drumming into their students not to be afraid to make positive changes and to demonstrate their technical capabilities. Students like graduate Luke Hickson, exemplify this approach.

Having started his MSc at the university in September 2019, Luke commenced his work placement with Fabricon, a design engineering business based in Lancashire, in January 2020. This placement was coordinated through the Made Smarter Programme³.

After graduating with his MSc, Luke was offered full-time employment with the company. He said:

“Through the MSc, I was given real hands-on experience, using the printers and this really helped me to transition to the workplace. I could see how it all fitted into the manufacturing process. I learnt about CAD design and was able to recommend changes to processes working alongside the production manager and this has created real efficiencies at Fabricon.

“I think PrintCity armed me to feel confident in my decisions, and the recommendations I was making. Admittedly, I have made some mistakes in my first year in industry, but the mentoring I was given on the MSc course has helped me to realise that these are part of the learning process.”

Luke is now putting his skills to work as a design and development engineer – and helping the engineering design firm to innovate and provide new services, thanks to the skills he learned during his degree programme.

Mark Bushdyhan, managing director at Fabricon, commented: “It is all too easy for businesses to become set in their ways. The beauty of this ‘PrintCity ecosystem’ is that it brings fresh eyes to industry, but from students who have benefited from a course designed to bridge the skills gap.”

Partnerships between education and industry are creating stepping-stones to develop future engineers and designers. Collaborations like these are already working to close the skills gap and modernise practices, helping British manufacturing to thrive.

¹ https://www.makeuk.org/insights/publications/uk-manufacturing-the-facts-2019-20#:~:text=With%20annual%20output%20of%20%C2%A3,manufacturing%20nation%20in%20the%20world The sector employs 2.7 million people, accounts for 45% of total exports – totalling £275bn.

² https://thebusinessjournal.com/skills-gap-a-big-challenge-for-employers/

³ Made Smarter is a national movement backed by world-renowned businesses and the UK government. We connect UK manufacturing industries to the digital tools, leadership, and skills they need to drive sustainable growth.

Add a Comment

No messages on this article yet