Epicor Software Corporation, provider of business software solutions for manufacturing, distribution, retail and services organisations, has announced that Vernay, one of the world's foremost manufacturers of flow control solutions for diverse industries, has selected the next-generation enterprise resource planning (ERP) solution from Epicor as its ERP system of record across its global enterprise.

With over 65 years of experience, Vernay is a trusted solutions provider to customers with the toughest fluid control challenges. Vernay's engineers and chemists are recognised throughout the industry for their expertise. Vernay's engineered components are used in everyday products including automobiles, appliances, printers, household cleaning products and lawn & garden equipment. They can also be found in critical applications including life-saving medical devices, water-saving irrigation systems and fuel cells.

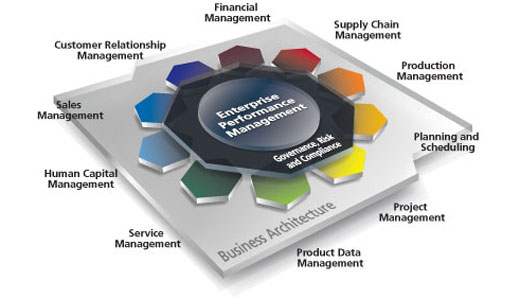

Vernay turned to Epicor and its next-generation Epicor ERP solution to replace an aged legacy ERP system that was unable to support the company's growing global operations. The technology investment will support improved competitive advantage by executing on the company's three strategic pillars -- globalisation, product design expertise (concept-to-launch) and lean operational excellence. The Epicor solution will support engineering, manufacturing, supply chain management, customer relationship management, marketing, sales, financial and HR management to help run and drive its manufacturing operations around the globe.

Vernay selected the powerful Epicor ERP solution for its flexibility to support its engineer-to-order and diverse manufacturing requirements. Vernay prides itself on its ability to partner with its clients to find the right design and material formulations to develop a flow control component or assembly that best satisfies the specifications of the particular application. This means that nearly every aspect of Vernay's operations are design-to-order -- entailing a wide variation in materials, processes, labour, estimating and quality controls.

The Epicor solution will integrate with Vernay's CAD-CAM systems to support engineering collaboration and documentation. The Epicor system also provides the flexibility to support Vernay's unique and best practice project management controls.

Vernay also will benefit from the solution's support for lean manufacturing initiatives and the Epicor Enhanced Quality module, a full-featured enterprise quality management software suite that will automate the business processes that are most critical to lowering operating costs and meeting Vernay's market-driven product quality requirements.

The Epicor system also will enable Vernay to track its labor and project costs and compare estimates to actuals to understand the cost implications of the finished product, so that it can improve its project estimating. The Epicor solution will also support Vernay's enterprise productivity objectives for lean administration, improved financial controls and governance. The company will also derive improved decision making and executive management support via enhanced operational visibility and shop floor data collection.

"Over the years, and working hand-in-hand with our customers, Vernay has gained a very strong reputation for having the experience and know-how to provide unique and reliable fluid control components," said Andy Woodward, global vice president of Sales, Marketing and Engineering of Vernay. "Our investment in the Epicor ERP solution will ensure we continue to be successful in our efforts to offer a world class concept-to-launch process, and will enable us as an organization to focus more time and energy on growing with our customers."

"The team at Vernay are leaders in their space -- the very best at what they do," said Kevin Roach, executive vice president and general manager, ERP Americas for Epicor. "The Epicor team is pleased to have a role in giving Vernay the capabilities they need to enable them to take their manufacturing operations to a whole new level -- on a global scale -- and to grow with the company and its business as it evolves in the future."

Add a Comment

No messages on this article yet