Epicor Software Corporation, provider of enterprise business software solutions for the midmarket and divisions of Global 1000 companies, has announced that Marshall Aerospace, one of the largest UK aircraft maintenance, engineering and operations companies, whose customers include the world's most respected names in commercial and military aviation, has selected the Epicor 9 next-generation enterprise resource planning (ERP) solution to underpin its business as part of a multi-phase change management project to transform the organisation's core business processes.

With an annual turnover of over 250m, nearly 1,800 staff and over 80 years of experience in the aviation engineering and support industry, Marshall Aerospace has built an enviable reputation as one of the world's premier suppliers of commercial and military aircraft maintenance and customizations. The company also owns and runs the UK's largest private airfield, at its 325 Hectare headquarters in Cambridge.

Epicor will replace a ten-year-old finance system, as well as many functions of an internally developed system, Tandem, which evolved over the last 20 years. A core team of seven business managers from across Marshall Aerospace will work full time on the project along with two IT consultants. Epicor will take over all human resource functions, purchasing, inventory, warehousing, sales processing, project management, and enable process enforcement across the business. Within the Aerostructures and Systems division, Epicor will also be providing full manufacturing functionality to enable the production and management of medium volume manufacturing runs, something this division has not had before.

"This is a huge business transformation project for Marshall Aerospace, that will not only unify our systems and processes across the organization, but provide an ERP platform to support our long-term strategic goals in line with our 'Horizon 2020' company growth strategy," said Alan Paul, head of ICT and security. "We're looking at all our processes and questioning how we can make them better. We'll be using Epicor to provide us with greater efficiencies and enforce the new processes we put in place. One of the key things we want to do is remove the islands of automation that exist and control our workflows across departments within a single solution wherever we can."

Marshall Aerospace's bespoke system, Tandem, will not be retired in phase one of the project as there are some specialised tasks, such as hangar scheduling, that will be reviewed in later phases. There will be a number of real-time interactions between Epicor and Tandem that are made possible by Epicor Service Connect, which, through workflows designed in a visual interface, is able to control the flow of information with absolute integrity between the two systems.

"Tandem has served us very well, but our existing finance solution has reached the end of its natural life," continued Paul. "One of the biggest challenges the IT team face, is that it has become increasingly difficult to introduce modern concepts into the system. Whenever there is a process, HR, or mandatory change this has to be manually programmed into the system. Epicor will allow us to remove that cumbersome step, improving processes in the IT department and the wider company."

Using Epicor's Business Process Management (BPM) features and Epicor Service Connect will allow Marshall Aerospace to separate its business logic from the underlying code. Whenever business rules and processes are revised these can be implemented without the need for outside consultants or programming. The visual interfaces within Epicor will enable the IT team to quickly implement these changes, while ensuring that any updates applied to the system will not break the workflows that have been put in place. Epicor comes with a number of best practice BPMs that have been refined for specific industries through thousands of implementations. Marshall Aerospace will be using these best practice elements where business efficiencies can be gained, and building BPMs and workflows for the new processes defined by the business transformation project.

Marshall Aerospace will also use Epicor to enforce project lifecycle management and moving the business to a position where all work is based around the concept of a project, rather than discrete sales orders. Marshall Aerospace's current process for sales orders is very complex, involving hundreds of line items. Tracking sales orders from estimate through to completion is difficult, particularly how an order performed against the original estimate. Moving to a project-based ERP solution will introduce Work Breakdown Structures (WBS) where it will be clear how individual project elements are progressing in terms of completion and cost. This information can be used in future bids to improve accuracy, and inform where manufacturing or business processes may need to be reviewed.

"Epicor was by far the most modern and flexible of the ERP systems that we reviewed. It has clearly been re-architected as a modern ERP system, not simply given a new skin, which was our suspicion of others," concluded Paul. "We were also impressed with the Microsoft Office integration features which allow our staff to work outside Epicor, in applications such as Outlook and carry out actions on workflow items. We found many of the other vendors to be quite dogmatic, whereas Epicor understood this was a business transformation project that would require flexibility from everyone to succeed."

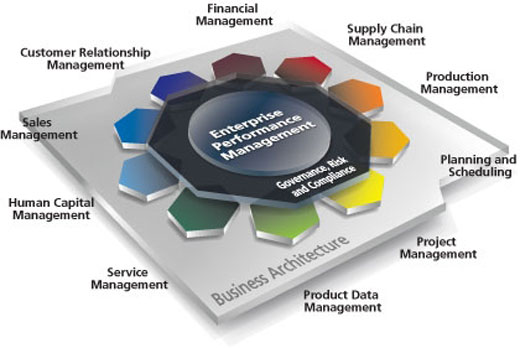

"We are thrilled that Marshall Aerospace has selected Epicor for this project, particularly given our wide ranging experience in the aerospace and defence industry," said Matt Muldoon, vice president for product marketing at Epicor. "Epicor's solution gives comprehensive features to meet strict product guidelines, compliance processes and quality assurance throughout the design and production phases of projects. Wherever needed, the solution has been engineered to meet the exactly requirements of this industry including project management, customer relationship management, and supply chain management."

Add a Comment

No messages on this article yet