| INFORMATION: Free information is available from Infosys Supply Chain Management on the subject in this story. Click here to request a copy |

Now is the time to take a fresh look at how best to classify inventory in the world of e-commerce, write Gopikrishnan GR, head of supply chain management practice, Infosys, Madhavan K Vasantham, Infosys SCM consultant, and Rajkumar B, Infosys SCM consultant.

Business-to-consumer (B2C) e-commerce continues its double-digit, year-on-year growth as sales patterns shift from conventional avenues such as stores to online channels. This is even more pronounced since online shoppers have been found to be less sensitive to real or perceived adverse economic conditions. However, this growth comes at a cost. There are already widespread worries around increasing customer dissatisfaction from slow online shopping websites, and the reasons for this span the entire fulfilment cycle. The result can be high shopping cart abandonment, which mostly translates to store abandonment as well.

Business-to-consumer (B2C) e-commerce continues its double-digit, year-on-year growth as sales patterns shift from conventional avenues such as stores to online channels. This is even more pronounced since online shoppers have been found to be less sensitive to real or perceived adverse economic conditions. However, this growth comes at a cost. There are already widespread worries around increasing customer dissatisfaction from slow online shopping websites, and the reasons for this span the entire fulfilment cycle. The result can be high shopping cart abandonment, which mostly translates to store abandonment as well.

A study by global Millennia Marketing1 highlights long checkout process as one of the top reasons for shopping cart abandonment, with 44 per cent of users citing this. With inventory checking emerging as the key bottleneck within the fulfilment process, retailers have been forced to re-think their inventory availability strategies to achieve faster web browsing without compromising on assured on-time deliveries. Their problems have been compounded by the fact that the sum total of product variants offered by these websites translates to over a million SKUs whose fulfilment complexities need to be managed at the back end.

Until now, online retailing businesses had metrics built around the primary focus area of on-time delivery. In fulfilment terms, this resulted in one of two sub-optimal scenarios; the upload of the entire inventory picture into the e-commerce front-end, or the shopper making synchronous inventory checks from the browser for each item in the cart. The trade-off with this deign approach has been an exponential increase in the load on websites and the resultant shopper frustrations with longer and unreliable order taking cycles. Reliability or performance? This has become a catch 22 situation for retailers.

So lets take a fresh look at optimising these two constraint variables (fulfilment accuracy versus shopping cart performance) by adopting a differentiated strategy for inventory visibility. We feel that our approach built around the principles of ABC classification of inventory and redesign of Available-to-Promise (ATP) rules and inventory refresh frequencies would lead to quicker response time at the web front end and significant decline in abandonment cases (see Chart A).

Traditional e-commerce ordering process flow

Chart A demonstrates the generic life cycle of an e-commerce order.

Within the order life cycle, inventory is checked at two points; first when the shopper makes an item choice (Add to Cart) and later during item confirmation (Availability Check and Reservation). Consequently, these two workflow steps end up being the most time-consuming processes for the online shopper.

In terms of inventory policies, websites currently use the following rule:

* Inventory is assumed to be Available-to-Promise if present in any of the warehouses (all Distribution Centres (DCs) Regular or Drop Ship). This check happens during the Add to Cart phase.

* Inventory can be reserved against the order only when available at the warehouse from where it can be shipped.

In this approach, all orders or order lines have to undergo mandatory inventory checks at the back-end, forcing capture/update of inventory position for each and every item.

Classification of inventory which inventory needs visibility the most?

Traditionally, the basic principle governing inventory management has been ABC Analysis, which in turn is loosely based on Paretos 80-20 rule. ABC Analysis is used to classify inventory into A, B and C class items. Once classified, inventory management of these items would be governed based on the class it belongs to, with Class A items getting most of the attention and Class C items the least. Applying this principle to the above order processing flow, we would recommend that only a select group of critical items classified as class A undergo the entire order promising process; including multiple inventory checks. The rest of the item requests can then be promised via a shorter processing cycle without the need to have real-time refresh.

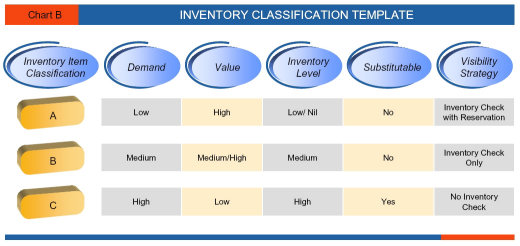

The ABC Inventory Visibility classification system would thus group items according to parameters such as sale frequency, item value or a similar relevant equivalent as per business rules of the online retailer. For instance:

Class A: High-value goods/make-to-order items with low demand such as furniture, jewellery, custom-made consumer items and high-end electronic goods. None of these items can be substituted with an equivalent and, hence, this class of inventory requires both inventory check and reservation. Items where demand history does not exist (eg. new product introductions), or where demand spurts occur due to promotional events, would get classified in Class-A inventory list.

Class B: Medium-value, medium-demand items such as certain electronic equipment, cameras and apparel. Typically, these cannot be substituted as the customers would be brand-sensitive in their choices. Inventory check needs to be done but reservation may be optional.

Class C: Low-value items with stable a demand pattern, such as milk. This category lends itself to substitution as it is not particularly brand sensitive. Inventory can be assumed to be infinite and, hence, does not need to be tightly controlled.

Chart B Inventory classification template

An online apparel retailer may not have the demand pattern for the current seasons range and would consequently find it difficult to predict the demand. However, demand for older designs would be stable as well as predictable, and so sufficient inventory can be maintained. Therefore, business can choose to classify standard designs as Class C items and the new designs as Class A or B, depending on past experience. Additionally, certain exclusive designs where inventory is limited can also be categorised as Class A. Also, common items such as socks and headbands can be assumed to have infinite availability. Each class of item calls for a different strategy in terms of inventory visibility, which is carried out at an item line level.

Class A

For all Class A items, the front end (order entry application) would mandatorily check the back-end inventory visibility system (order fulfilment solution) for each item before confirming an order inventory reservation would also be carried out to ensure availability to the customer.

Class B

For Class B items, a near real-time inventory availability snapshot would be made available at the front end to enable immediate checks during the checkout process via scheduled refreshes from the back-end system. If the available value at the front end for a particular item is lower than a set threshold, then a real-time system call is made to the inventory master for checking availability. These thresholds can be sub-category or item-specific. Reservation would be optional.

Class C

Class C items can be easily substituted; hence the inventory picture need not be maintained either at the front end or at the inventory visibility system; thus deeming these items to be always available. Whenever service of an item is stopped, the catalogue master is updated directly. By foregoing inventory capture, a substantial reduction is achieved in the inventory synchronisation load at the front end, given the fact Class C items typically form the majority of items sold.

This classification system helps in building the balance between maintaining and synchronising a huge inventory picture and ensuring accurate inventory information. A key aspect here is the inventory classification itself. For this we recommend using the analytics system typically used for parsing through web-traffic data at the front end as the primary input. Periodic updates to the classification based on the trends from the analytics engine can be uploaded to the back-end fulfilment solution in real time.

Business case

For an implementation at a US-based online specialty retailer, Infosys integrated the customised web front-end with Sterling SCM Suite, which was the order management system owning the inventory master record. The ABC inventory classification strategy has been adopted with respect to determining front-end inventory visibility. With a product range of over a million SKUs serviced through its e-commerce site, an inventory check for all the items would have led to severe deterioration of site performance and availability. Factoring in this constraint, the following approach was taken to provide inventory visibility.

Inventory visibility strategy

We deployed Sterlings activity-based real-time availability monitor, which updates the inventory picture at the front end at regular intervals based on the changes to supply and demand picture for each item. Different inventory thresholds (high, medium and low) were set up in the monitor such that whenever the inventory crosses any of these thresholds, the respective inventory status is published to the front end (see Chart C).

Chart C: Business process flow

For this implementation, the high and medium inventory levels were clubbed together (Class B + Class C), with neither inventory check nor reservation being carried out at the front end. If the inventory level equals low (Class A), inventory check and reservation is performed prior to confirming the order. A different approach for medium inventory level items has not been adopted here as there was not a significant number of items falling in this category.

However, definition of inventory threshold limit became a major challenge as it can vary from one item to another. At present, Sterling Commerces SCM Suite 8.0 supports configuring common inventory thresholds for all items as part of the monitor rule setup. But, configuring individual monitoring rules for each item does not promise a good design. To a certain extent, the problem can be overcome by using a finite set of monitoring rules by grouping a set of items at the same threshold level (item group concept). However, an enhancement to the product for enabling the monitor to dynamically fetch the inventory thresholds for an item will provide flexibility for item-based monitoring.

Vendor agnostic

As a consultancy, Infosys is SCM solution vendor agnostic, recommending a range of proven solutions from vendors such as SAP, Oracle, Sterling Commerce, IBM Maximo and Microsoft. In the online retail space where there may be multi-channel situations, multiple front ends, an EDI requirement, an online catalogue and multiple back-end souring options through multiple warehouses, etc., our main criteria is that the SCM system needs to be state-of-the-art and robust.

Efficient and speedy operation

The traditional default way of achieving a real-time picture of inventory in the online retail sector is to take the one-size-fits-all route. But, ultimately, online retailers need to determine how they can classify different types of inventory items in order to both look to guarantee ready availability of product and to ensure that customers can be notified of the availability of a product almost immediately as they shop online. Whether you want to call this ABC, or inventory control based on category, or demand pattern categorisation, or whatever terminology you feel most appropriate, it essentially adds up to the same principle, which we believe is the most sound for the efficient and speedy operation of an online retail business.

Conclusion

With the amount of data growing by the day, any e-commerce system for online retailers will have to take a comprehensive approach to front-end inventory visibility by striking a balance between site performance and accurate fulfilment to realise a comprehensive user experience. With online retail store experience being a key focus area among various channels, we believe companies need to slice and dice inventory consumption patterns and feed these as an input to optimised solution design. In this context, we believe that our recommended way forward of ABC classification of items for inventory visibility and fulfilment would go a long way in balancing the twin challenges of fulfilment accuracy and online store system performance.

Appendix

A traditional definition of ABC Classification System2 is as follows:

A class inventory will typically contain items that account for 70 per cent of total value.

B class inventory will have around 20 per cent of total value.

C class inventory will account for the remaining 10 per cent.

Source: www.wikipedia.org

References

Shopping Cart Abandonment Survey by Global Millennia Marketing. www.globalmillenniamarketing.com/shopping%20_cart_abandonment_survey.htm

ABC inventory classification from wikipedia.org

Infosys at a glance

Infosys defines, designs and delivers IT-enabled business solutions that help Global 2000 companies win in a Flat World. These solutions focus on providing strategic differentiation and operational superiority to clients. With Infosys, clients are assured of a transparent business partner, world-class processes, speed of execution and the power to stretch their IT budgets by leveraging Infosyss Global Delivery Model. Infosys has over 100,000 employees in over 50 offices worldwide, and is part of the NASDAQ-100 Index and The Global Dow. For more information visit: www.infosys.com

Infosys in Supply Chain Management

Infosys in Supply Chain Management

Infosys enables worlds leading organisations to unlock value from their supply chain by providing pertinent solutions that cover the spectrum of extended organisation- Demand Planning, Supply Planning, Sourcing & Procurement, Supply Chain Execution and Enterprise Asset Management. With a wide range of package-driven solutions and accelerators, the company has a track record of turning the most complex supply chain situations into seamless delivery pipelines. Infosys has a strong alliance focus with key supply chain product and technology solution providers; including SAP, Oracle, Sterling Commerce, IBM Maximo and Microsoft to provide services on packaged supply chain applications. Learn more about Infosys capabilities in SCM at: www.infosys.com/supply-chain

Add a Comment

No messages on this article yet