When a large international peace keeping organization needed to ship computer equipment to distant and often dangerous countries such as Bosnia, Republic of the Congo and Mozambique, they decided to outsource the logistics to the same company that sold them the IT equipment. In doing so, the organization saved $5 million dollars of uplift costs that would have been applied if a third party was used. In this case outsourcing was the right decision, but can it also be a wrong decision?

The complexities of maintaining a competitive supply chain continues to increase with the globalization of business. For example, according to Forrester Research, US exports increased by 4 percent between 1999 and 2003, compared with a 23% increase in imports; that means one out of five containers heading to a US port will return empty to its origin resulting in a $5 billion annual expense worldwide, an expense that comes directly out of the bottom line of global importers and exporters. On top of these costs, keeping the entire supply chain discipline can drain key skills that detract from other strategic activities important to any business.

For many businesses supply chain outsourcing is nothing new. For several years now many multinational businesses have turned to individual trade services providers, such as their logistics network managers/3PLs, or banking or financial service managers to run parts of their supply chain, but in todays reality these providers lack the deep end-to-end skills and capabilities that are required.

Today multinational businesses need an end to end logistics provider or what Noha Tohamy , supply chain analyst at Forrester Research calls a global trade orchestrator (GTO) to handle all of a clients logistics needs. According to Tohamy several GTO providers are beginning to emerge including, IBM, TNT Logistics and DHL.

THE MARKET

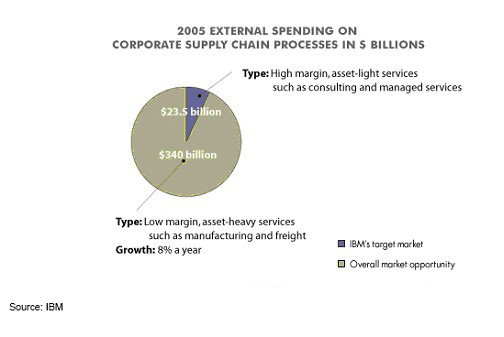

IBM calculates that, out of the $3.4 trillion spent on supply chains this year, $340 billion will go to outside service providers. Until now, firms have spent most of this money on asset-heavy services such as manufacturing outsourcing, warehousing and freight services, and on deploying costly software applications. These spending patterns have begun to change and in a world that requires on demand modes of operation, companies need to respond dynamically to all manner of changes.

Today, companies see supply-chain management as a way of improving both sales and profits and chief executives see it as a competitive advantage. For example, IBMs supply chain has not only improved customer satisfaction, but it as also generated millions of dollars for the IBM Corporation and its shareholders - money that can be used for acquisitions or other strategic purposes, thus contributing to the bottom line.

Increasingly, companies want help not just with manufacturing or procurement or logistics alone, but the entire supply chain from opportunity to cash. They need to integrate the entire supply chain and to do so in a way that preserves flexibility, opens their enterprise infrastructure to the innovation, expertise and networks of others, and lets them shed the pieces of the supply chain that can be better run by trusted partners. IBM calculates that the market for these high margin, asset-light services is worth $23.5 billion with a growth rate at 6-15% a year.

EXPERTISE AND SCALE

To thrive in this new market, supply-chain service providers will have to master new skills and disciplines. These include deep business and industry knowledge, applied technology skills, hands-on engineering know-how, and proven supply-chain intellectual property and physical assets. For its part, IBM recently announced a new Supply Chain Business Transformation Outsourcing solution, which offers clients end-to-end supply chain management performance improvements, including logistics, procurement outsourcing, and supply chain optimization services, leveraging the experience from IBM's own supply chain transformation.

With this experience, IBM believes it has a competitive edge, since it has removed billions of costs by transforming supply chain operations. As an example, IBMs Global Logistics division has changed its fixed/variable cost structure from 50 percent variable to 93 percent variable, reduced IT logistics applications by 80 percent, and achieved more than $1.1 billion in year-to-year cumulative cost savings. This occurred simultaneously while shipping weight and product shipments increased by 9 percent and 31 percent, respectively.

WHEN OR WHEN NOT TO OUTSOURCE

Outsourcing the supply chain is not a one size fits all decision and it not something that should be taken lightly. Many analyst firms such as AMR Research recommend to "start small, reap benefits, and evolve over time. IBM will work with prospective clients to show the sustainable value to be delivered by end-to-end supply chain management improvements, suggesting that the journey can begin wherever the client's process is experiencing the most pain.

The outsourcing of any environment whether its finance, human resources, or parts of the supply chain can deliver several benefits and companies need to first start by analyzing their existing processes and look at culture for feasibility. For example, NiSource, a Fortune 500 company engaged in natural gas transmission, storage and distribution, as well as electric generation, transmission and distribution, recently announced that it is outsourcing human resources, finance and accounting, supply chain, customer contact, meter-to-cash (billing and collections) and information technology. The companys CEO had this to say about the deal, "this agreement will enable NiSource to transform its business to further focus on core strengths of providing safe, reliable utility and pipeline services to our customers," said Gary L. Neale, NiSource chairman and chief executive officer. This is a perfect example of an ideal environment for turning over specific operations to a trusted partner. In this case, NiSource, realizing that it wants to stick to its core competencies and let an expert worry about its day to day non-strategic business activities.

So is outsourcing right for you? It depends on your own situation and assessment of incremental vs. rapid improvements, but the advantages are clear.

Linda Cantwell joined IBM in 1982 where since she has served in a variety of roles, in IBMs Procurement organization, in Software Manufacturing, IBM Global Services), and now driving a new business initiative for the IBM Integrated Supply Chain (ISC).

Linda Cantwell joined IBM in 1982 where since she has served in a variety of roles, in IBMs Procurement organization, in Software Manufacturing, IBM Global Services), and now driving a new business initiative for the IBM Integrated Supply Chain (ISC).

In January of 2003, Cantwell was named to the position of Vice President for Global Strategic Sourcing in IBM Global Procurement. She and her global team were responsible for the management of global sourcing strategies and execution in support of IBMs global supplier expenditures that were approximately $20B in 2003. In February of 2004, she was named to her current position of ISC Vice President of Business Growth Initiatives. This is a new business area that seeks to leverage the assets and skills of the ISC team for greater value to IBMs clients.

Cantwell is a graduate of Pennsylvania State University, with a degree in Finance. She lives in Cornwall, New York with her husband, John.

Add a Comment

No messages on this article yet